- Very robust seal

- Multiple sealing lips for positive seal

- Easy replacement in the field with split rings

- Extensive range of sizes

- Can be used with poor counter surfaces

- Operating temperatures of -49°F to +500°F / -45°C to +260°C depending on the elastomer

- Compatible with virtually all media

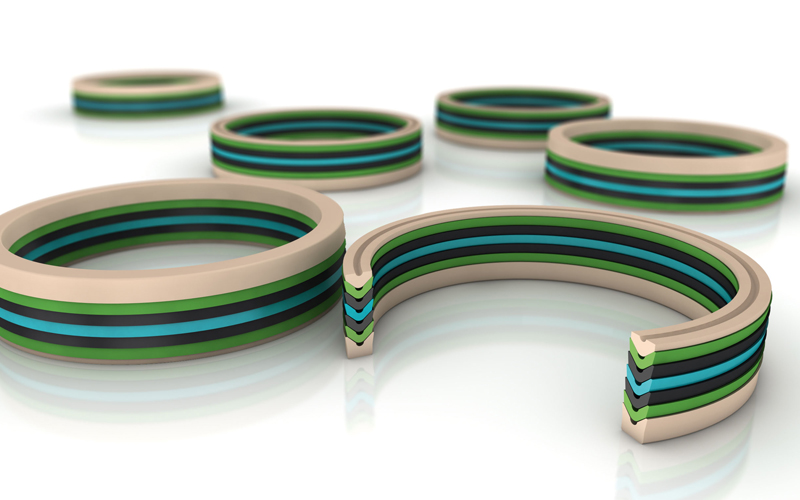

The V-Stack seal assembly is made up of a nest of Chevron rings comprising a top adapter or anti-extrusion ring (1), Vee Rings (2) and a bottom adapter (3). In the assembly the energizing axial force is transferred between the individual packing rings so that each ring is pressed into positive contact with the mating hardware surface. Special material grades are available for a large variety of working conditions.

The top adapter or anti-extrusion ring is manufactured from a high modulus plastic, typically PEEK™, to resist extrusion. This component supports the Vee Rings, providing stability and extrusion resistance.

- In the standard version Vee Rings are made entirely of Turcon® or combinations of Turcon® and elastomers (Isolast®, XploR™) to give good resilience, sealing efficiency and extrusion resistance.

Due to their specific design, Vee Rings are sensitive to fluid pressure variations, enabling them to deflect throughout their radial section, increasing the seal loading and effectiveness in proportion to the pressures applied.

- The bottom adapter ring is manufactured from PEEK™ or PTFE. The function of this component is to ensure a uniform pressure distribution.

Typical Oil & Gas Applications Include:

- Electrical logging: Logging While Drilling (LWD) / Measurement While Drilling (MWD) Tools

- Drilling and steerable tools

- Reservoir sampling tools

- Wellheads: tubing hanger seals & flow control tools

- Risers and Compensators

- Gas lifts

- Sub surface safety valves and valve stem seals

- Polished bore receptacles

- Sliding sleeves

Download the Turcon® V-Stack Flyer

| Parameters | Values |

|---|---|

|

Operating Pressure |

Up to 30,000 psi / 207 MPa with custom components |

|

Speed |

Up to 3.3 ft/s / 1.0 m/s depending on material |

|

Temperature Range |

-45 °C to +260 °C / |

|

Media |

Drilling mud, downhole fluids, seawater, hydraulic fluids including water glycol based fluids |

Please contact your local Trelleborg Sealing Solutions marketing company.